Single-Cut vs Double-Cut: Which Carbide Burr to Choose?

Carbide burrs—also called tungsten carbide burrs—are widely used in metalworking, woodworking, mold making, and automotive applications. Made from durable tungsten carbide and shaped with high-precision CNC engraving, they come in many shapes and cutting textures. One key choice is between single-cut and double-cut burrs, each suited for different materials and tasks. This blog explains what they are, their differences, and how to choose the right one.

1. What Are Single-Cut and Double-Cut Carbide Burrs?

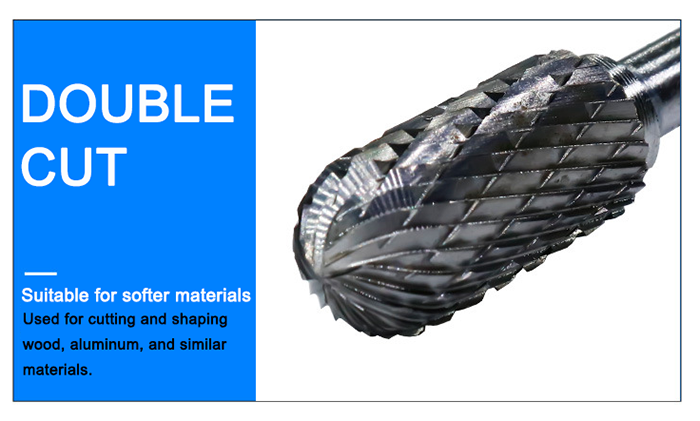

Carbide burrs come in two main cutting styles based on their flute patterns: single-cut and double-cut. Single-cut carbide burrs feature flutes running in one direction, offering fast material removal and making them suitable for harder metals. In contrast, double-cut carbide burrs have flutes cut in two directions to create a criss-cross pattern, which produces smaller chips, provides smoother control, and is ideal for softer materials and detailed finishing.

2. Key Differences Between Single-Cut and Double-Cut Burrs

1).Materials: Single-cut burrs are ideal for hard metals like iron, steel, stainless steel, and copper, while double-cut burrs work best on softer materials such as wood, aluminum, plastic, and softer metals.

2).Chip Removal: Double-cut burrs feature a denser cross-cut pattern, which improves chip extraction, reduces clogging, and allows smoother, more efficient operation.

3).Surface Finish: Double-cut burrs produce a finer, smoother finish, making them suitable for polishing and detailed work, whereas single-cut burrs tend to leave rougher surfaces due to their more aggressive cutting action.

4).Control and Handling: Single-cut burrs can be harder to control, especially for beginners, and may cause “burr jumping.” Double-cut burrs offer steadier, easier handling, providing better precision and safer operation.

3. Which One Should You Choose?

Here’s a simple guide based on your needs:

✔ If You’re New to Carbide Burrs → Choose Double-Cut

Double-cut burrs offer better control, smoother cutting, and fewer mistakes.

✔ If You’re Working on Hard Metals → Choose Single-Cut

Their strong, directional flutes remove hard metal efficiently.

✔ If You Need High Surface Smoothness → Choose Double-Cut

Especially suitable for finishing, engraving, and polishing tasks.

Conclusion

Choosing between single-cut and double-cut carbide burrs depends on the material you’re working with, the surface finish you need, your operation experience, and the type of work—whether rough grinding or fine finishing. In short, single-cut burrs are perfect for hard metals, offer fast material removal, but leave a rougher finish, while double-cut burrs are ideal for softer materials, provide smoother finishes, and are easier to control. Selecting the correct burr type will improve efficiency, extend tool life, and deliver better results in your projects.

Post time: Nov-14-2025