The Simple Guide to Choosing the Right TCT Saw Blade Tooth Count

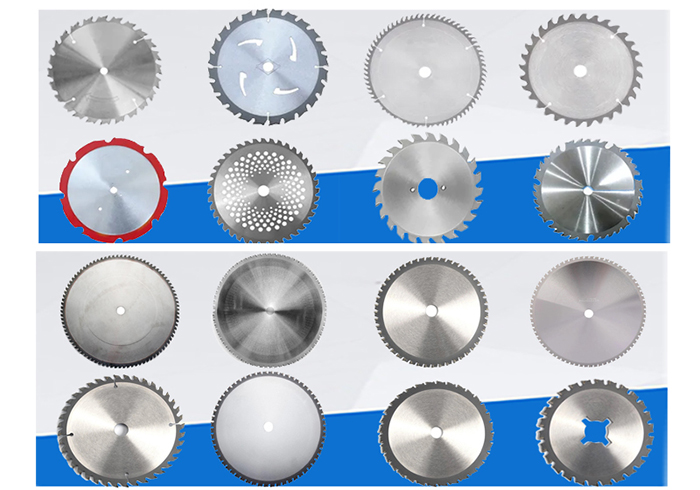

Picking the wrong tooth count for your TCT saw blade is a common mistake that costs time, money, and can ruin your workpiece. Cut through the confusion with this straightforward guide. We'll explain how tooth count changes the game for different materials, so you can make the perfect choice every time.

Why Tooth Count Matters: It's All About the Balance

Think of tooth count as a simple trade-off: fewer teeth cut faster, more teeth cut smoother.

A blade with fewer teeth (like 24-40) has deep gaps between them. These gaps allow for fast chip removal, which means the blade can power through material quickly. However, the cut edge will be rougher. It’s like using an axe to chop wood—fast and efficient, but not precise.

A blade with many teeth (like 80-100+) makes more, smaller cuts per revolution. This results in a much cleaner, polished edge. The downside is a slower cutting speed and a greater tendency to heat up if used on the wrong material. It’s like slicing bread with a fine-toothed knife—smooth and clean, but not for a loaf.

The goal is to match this balance to your specific job.

Choosing by Material: Your Quick-Reference Guide

The material you're cutting is the most important factor. Here’s how to choose.

For Wood & Sheet Goods:

For general-purpose woodworking, a 40-60 tooth blade is a great starting point. It handles crosscuts and rip cuts reasonably well. When you need to cut thick, soft wood quickly—like framing lumber or rough plywood—reach for a blade with fewer teeth (24-40). The aggressive bite and good chip clearance prevent overheating.

For fine woodworking, veneered plywood, or melamine-coated boards where a chip-free edge is critical, you need more teeth (60-100+). A high-tooth-count "finish" or "crosscut" blade will slice cleanly through the material and its delicate surface without tear-out.

For Aluminum & Non-Ferrous Metals:

Aluminum is sticky and can quickly gum up a blade. For general aluminum cutting, blades with 60-80 teeth are common. They strike a good balance between a decent finish and efficient chip clearance, which is vital to prevent heat buildup.

For cutting thin aluminum tubing or sheet, or when you demand a near-polished edge, opt for a blade with 100-120 teeth. Remember to always use a lubricant like cutting wax or a specialized fluid to keep the blade cool and prevent material from welding to the teeth.

For Plastics & Composites:

Materials like acrylic, PVC, and laminates melt easily from friction. The golden rule here is to use a blade with many teeth (80+) and ensure it is very sharp. A sharp, high-tooth-count blade makes clean cuts with minimal heat. Always feed the material steadily—pushing too slowly can actually generate more heat from friction.

Pro Tips for Better Results & Safety

▪Match the Blade to Your Saw: The blade's arbor hole must fit your saw's spindle perfectly. Never use reducers or make-shift solutions. Also, never run a blade faster than its maximum RPM rating, which is stamped on its body.

▪Consider the Kerf: A thin-kerf blade (thinner body) removes less material, requires less power from your saw, and is great for finer work. A standard full-kerf blade is more robust and better for heavy-duty, straight cuts.

▪Listen to Your Saw: If your saw struggles, burns the material, or produces ragged cuts, stop. This usually means the blade is dull, the tooth count is wrong for the job, or you're feeding the material too fast or too slow.

▪Respect the Blade: Always wear safety glasses and hearing protection. Ensure the blade guard is working and that your workpiece is firmly secured before making a cut.

The Bottom Line

There's no single "best" blade. The best blade is the one perfectly suited for your material and your desired finish. Start with the recommendations above, and you’ll be on the right track. For your most common tasks, investing in two dedicated blades—one with lower teeth for fast, rough cuts and one with higher teeth for fine, finish work—will transform your results.

Ready to make cleaner, faster, and safer cuts? Explore our range of purpose-built TCT saw blades, each designed to excel with specific materials. Find your perfect match on our website.

Post time: Jan-23-2026