Decoding Tap Tolerances: From H4 to 7G— How to Choose the Right Thread Precision

Tap tolerance plays a critical role in determining the final accuracy, fit, and assembly performance of internal threads.

However, tolerance markings on taps are often misunderstood, leading to improper tool selection and avoidable machining issues.

This article explains how tap tolerances relate to internal thread precision and how to select the appropriate tolerance for different applications.

Core Concept: Tap Tolerance vs. Internal Thread Tolerance

First, a fundamental relationship must be understood: The tap's tolerance determines the possible tolerance range of the internal thread it produces. Think of a tap as a precision "mold"; its dimensional accuracy is directly "copied" onto the workpiece.

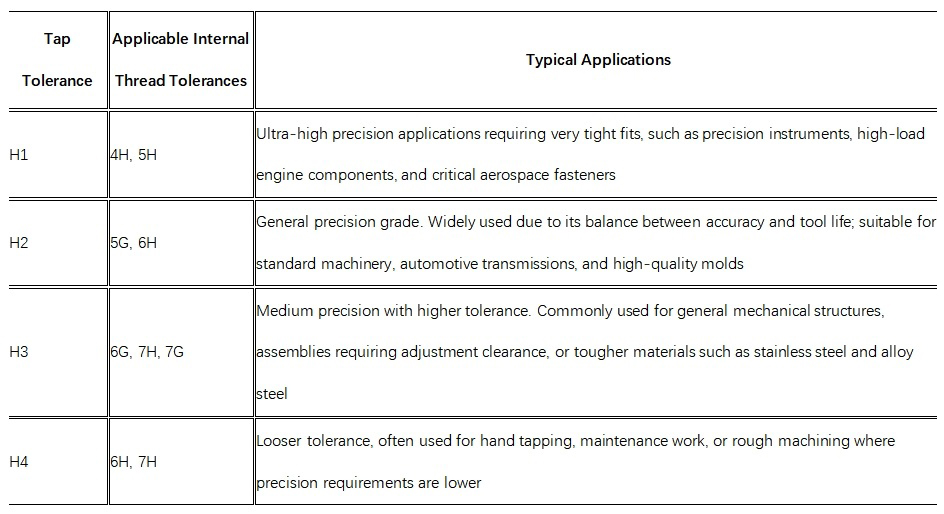

▪Tap Tolerance Zone: This refers to the manufacturing precision range of the tap itself, typically denoted by codes like H1, H2, H3, H4 in Chinese standards (GB/T). A smaller number indicates a tighter tolerance zone and a more dimensionally precise tap (though often with reduced wear resistance).

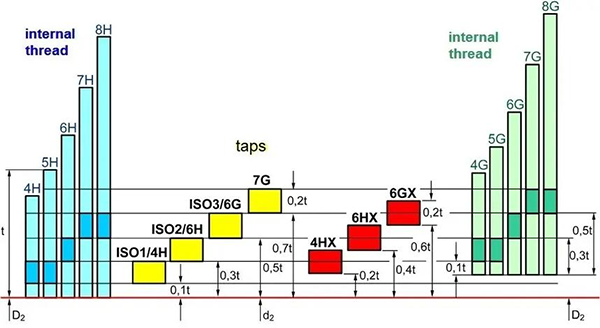

▪Internal Thread Tolerance Zone: This refers to the allowable size range of the finished thread hole in the workpiece, commonly marked with codes like 4H, 5G, 6G, 7H, 7G. Here, "H" indicates a tolerance zone positioned on or above the pitch diameter basic line, while "G" indicates a zone generally positioned below it, providing more clearance.

The relationship is not one-to-one. A tap with a specific tolerance zone can consistently produce internal threads within 2-3 different tolerance grades. For clarity, refer to the core selection guide below, compiled based on standards like GB/T 968-2007.

#Tap to Internal Thread Tolerance Reference Chart#

*Critical Note: The chart above is a foundational reference. In practice, final thread accuracy is also influenced by workpiece material properties, cutting parameters, coolant, and machine tool stability.

How to Select Tolerances Based on Application Requirements

Step 1: Define the Internal Thread Requirement

▪Tight, secure fit → choose an H-position internal thread tolerance (e.g., 6H)

▪Allowance for coating or easier assembly → choose a G-position internal thread tolerance (e.g., 6G), providing extra clearance for surface treatments or faster assembly

Step 2: Match the Appropriate Tap Tolerance

Once the internal thread tolerance is determined, select the corresponding tap tolerance band from the reference table.

▪H3 taps are commonly used for producing 6G or 7G threads.

▪For difficult-to-machine materials (e.g., titanium alloys, high-hardness steels), operators may select slightly looser taps (e.g., H4) to improve chip evacuation and extend tool life.

Step 3: Pay Attention to Special Markings

High-quality taps may include designations such as “6HX”, indicating enhancements for wear resistance or suitability for abrasive materials.

For taps intended for coating processes, manufacturers may recommend a slight oversize to compensate for coating thickness and maintain target tolerance.

Conclusion

Selecting the right tap tolerance requires balancing thread precision, tool life, and workpiece material. Understanding the difference between “H” and “G” tolerances and using reference tables as a guide—rather than a strict rule—helps ensure reliable threads, smooth assembly, and cost-effective machining.

Post time: Dec-19-2025