International Standards for Tap Dimensions

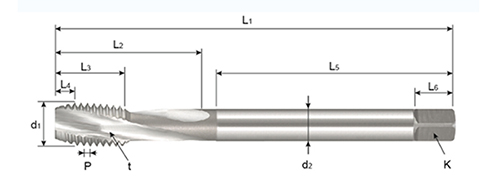

The structural dimensions of taps are clearly defined in international standards. Common ones include:

•DIN (European/German standard)

•ISO (International Standard)

•JIS (Japanese Industrial Standard)

•ANSI (American National Standard)

In the DIN standard, different styles are specified:

Coarse Shank Tap (DIN 371) :

When machining small diameter threads (coarse threads with diameters ≤10mm), to ensure adequate tap strength, the shank diameter (d₂) is made greater than or equal to the cutting diameter (d₁), hence the name "coarse shank tap".

Specifically:

•When d₁ < 6mm, then d₂ > d₁

•When 6mm ≤ d₁ ≤ 10mm, then d₂ = d₁

Therefore, for M10 and below, DIN 371 coarse shank taps are commonly used.

Fine Shank Tap (DIN 376 / DIN 374) :

When machining larger diameter threads (d₁ ≥ 12mm), the tap has sufficient strength, so the shank diameter (d₂) is made less than the cutting diameter (d₁), thus called "fine shank tap".

However, in some special cases, such as tapping deep holes or where there is a long overhang, if the thread depth exceeds the working length of the tap, fine shank taps may also be used even if d₁ < 12mm.

In other words, while fine shank taps are generally used for threads of M12 and above, they may also be used for sizes below M12 depending on the application.

Additionally, for fine-pitch threads, due to lower cutting forces, DIN 374 fine shank taps are often preferred.

Post time: Apr-09-2025