Products

Hot sale professional M35 Cobalt twist drill bit straight shank for metal drilling

Product Description

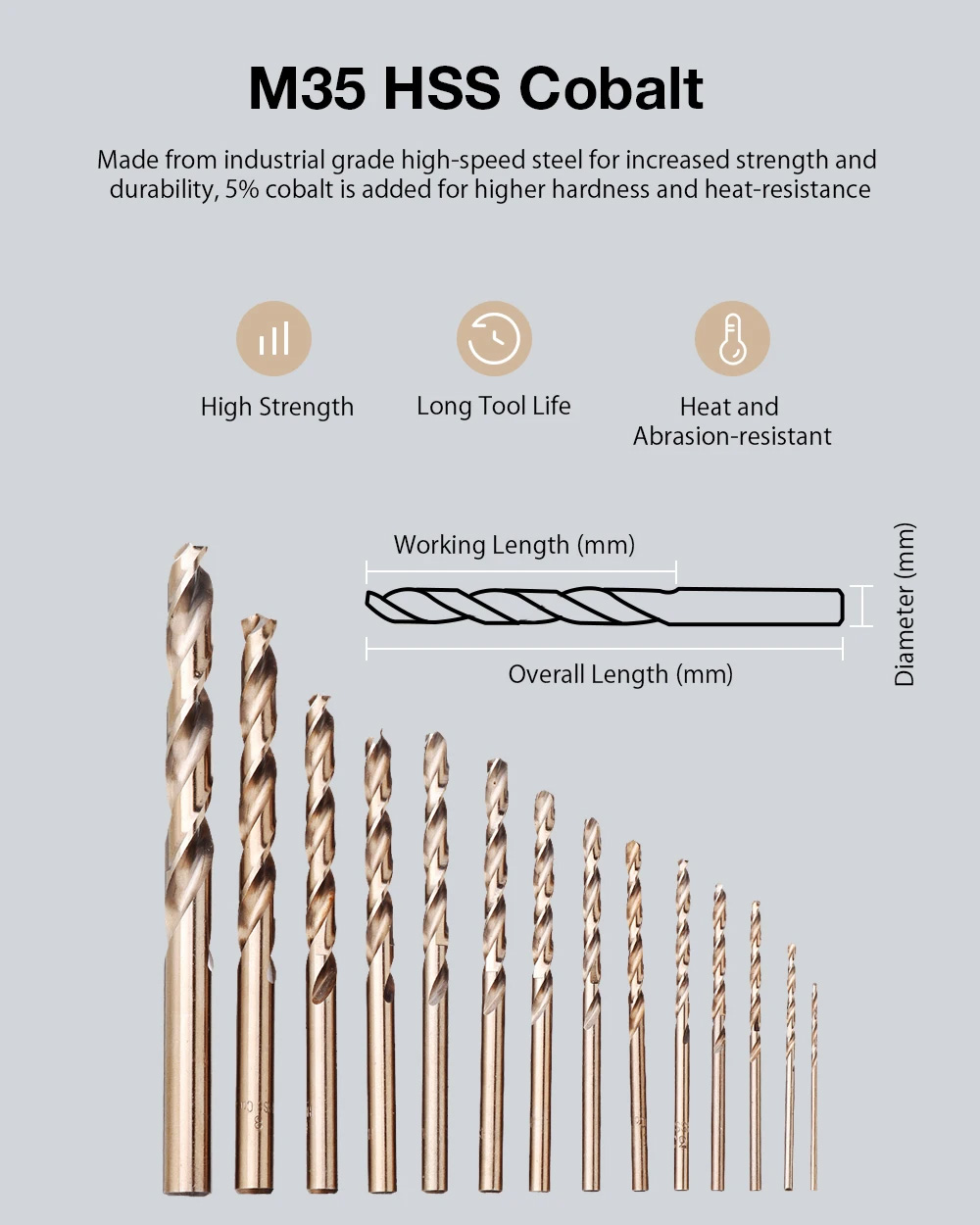

1.[High quality material]: M35 cobalt. Added 5% cobalt to improve hardness and heat resistance. The Rockwell hardness is up to 65. It has a faster cutting speed and a longer service life, which is 12 times that of an average HSS bit.

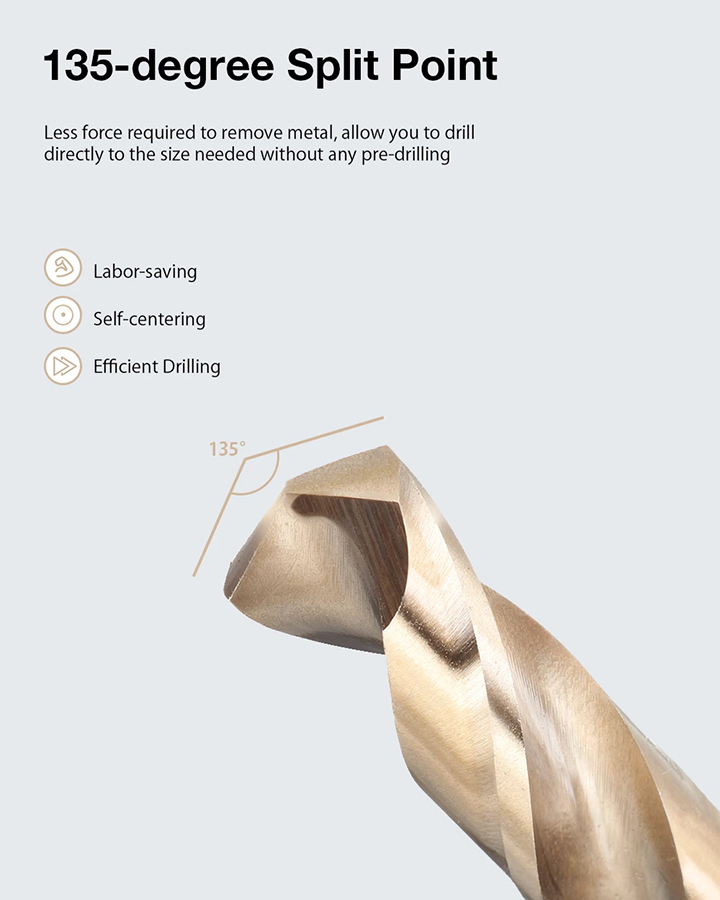

2.[Accurate Card Position]: Self-centering. The guiding separation point of the 135° rapid cutting is automatically centered and can be penetrated quickly under a small pressure. The straight shank can be firmly fixed and accurately centered, suitable for standard drill trays and conventional circular trays.

3.[Efficient and fast]: High-efficiency drilling can be carried out without walking. Remove debris and particles faster and easier.

4. [Low cost]: The lowest cost of drilling each hole. The solid cobalt steel drill bit can be reground.

5. [Split point]: You can drill directly to the required size without pre-drilling

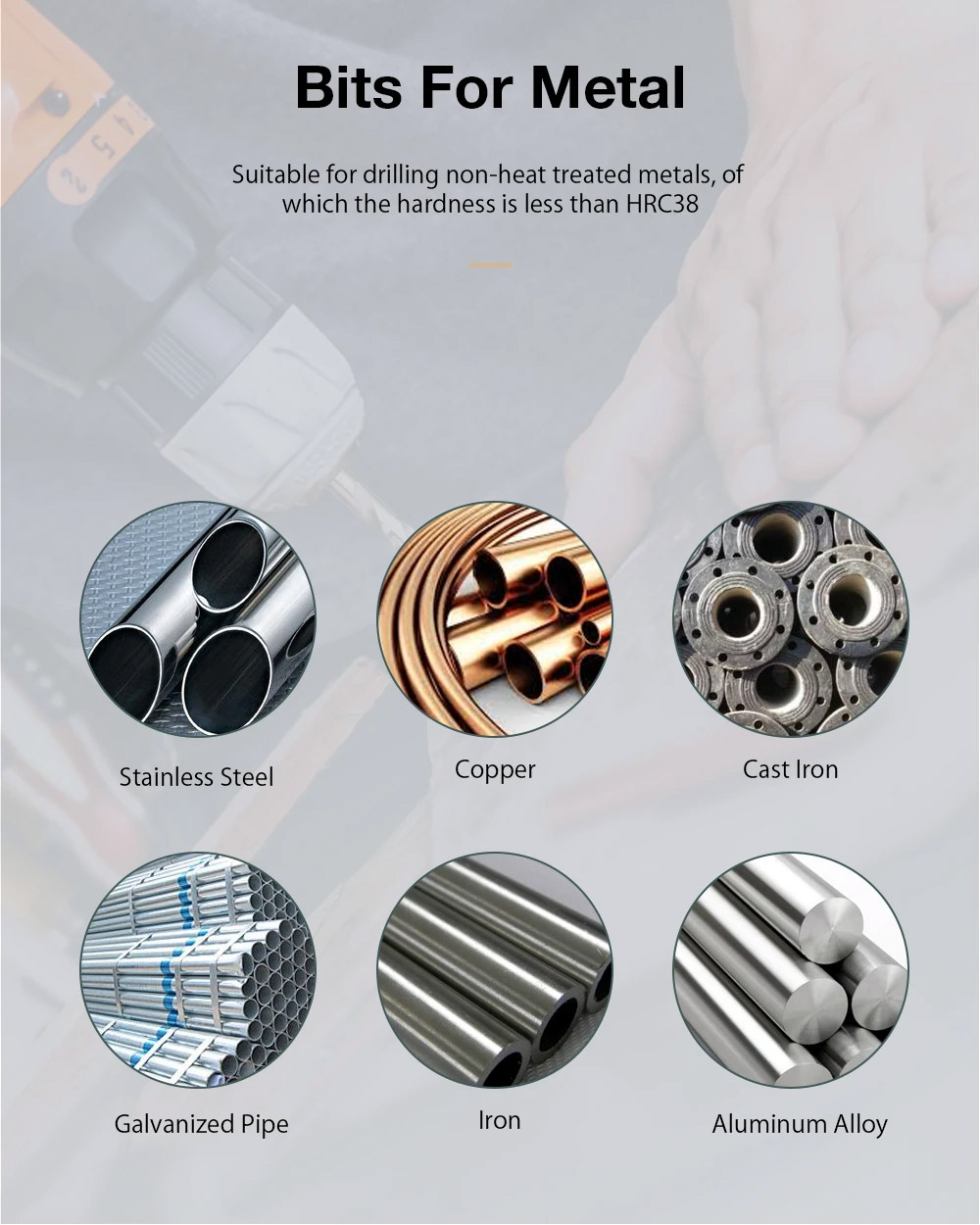

6. [Widely used]: Suitable for drilling stainless steel, copper cast iron, galvanized pipe, iron, aluminum alloy and other non-heat-treated metals whose hardness is less than HRC38. Not suitable for hardened steel/high carbon steel. If it cannot penetrate, try to adjust the speed.

|

Material |

HSSM42, HSSM35, HSSM2(6542), HSS4341, HSS4241 |

|

Process |

fully ground, edge ground/half ground, roll forged, milled |

|

Standard |

DIN338, DIN340, DIN1897, DIN1869 |

|

Split Point |

118°and 135° tip both available |

|

Stamping |

laser marking and (letter) stamping. |

|

Shank |

Straight shank(Tri-Flats shank,Hex shank,Round shank,Morse taper shank) |

|

Available Packing |

single sleeve packing, sandwich packing, blister packing, square plastic |

|

Surface Color |

black flute & golden shank, black flute & white shank, bright finished, |

|

Diameter Size |

0.5-20mm. 1/16"-1", A-Z, 1# - 90# |

|

Total Length |

2.5-140mm |

|

Features |

1.HSS m35 drill bits are more expensive than other drill bits, but if you regularly drill through metal, they are a good investment since they tend to last longer. |

Product Features

1.HSS m35 drill bits are more expensive than other drill bits, but if you regularly drill through metal, they are a good investment since they tend to last longer.

2.No center punch is needed—the aggressive 135° Quick-Cut points are self-centering and penetrate quickly with less pressure. Will not "walk" or "wander".

3.Precision ground point, flutes, body, clearance and drill diameter for the ultimate in accuracy and performance.

Product Details

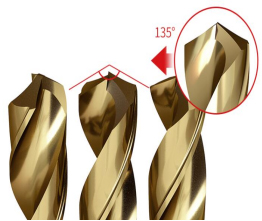

118° and 135° split points

The 118° point angle is mainly used for softer materials such as mild steel and cast iron.

The 135° split point is used for cutting hard steel, especially for deep holes that are more than 4 times the diameter of the drill bit. Using the 135° split point, cutting harder materials produces thicker chips, minimizing work hardening of the cavity.

Spiral fluted shank

Fully ground body construction. High flow spiral design for the fastest removal speed and for thick material

Straight shank

Straight shank for standard chuck,

less "walking" or "wandering."

The end of the shank is chamfered

to allow an easy and firm grip.

Special SST heat treatment of bronze

and surface.

HSS Twist Drill Bits RPM

NOTE: Bigger diameters, slower rotation speed.

- Cobalt drill bits require slow RPM when drilling metals. The suggested RPM is only for your reference. It may vary from different materials. You can start from a lower RPM and adjust it higher slowly. Once the bit can get into the work piece. the adjustment should be stopped. Punching more than 2mm add coolant to continue punching, is to extend the life of the drill bit.

|

Twist Drill Bits Diameters(mm) |

RPM(R/Min) |

Application |

|

1mm-2mm |

3000-1800(r/min) |

|

|

2mm-3mm |

1800-1400(r/min) |

|

|

3mm-4mm |

1400-1000(r/min) |

|

|

4mm-5mm |

1000-800(r/min) |

|

|

5mm-6mm |

800-700(r/min) |

|

|

6mm-7mm |

700-600(r/min) |

|

|

7mm-8mm |

600-500(r/min) |

|

|

8mm-9mm |

500-400(r/min) |

|

|

9mm-10mm |

400-350(r/min) |

|

|

10mm-11mm |

350-300(r/min) |

|

|

11mm-12mm |

300-280(r/min) |

|

|

12mm-13mm |

280-250(r/min) |

|

|

14mm |

220(r/min) |

|

|

15mm |

200(r/min) |

Product Application

|

Material |

Suitable for drill holes | ||||||||

|

Stainless Steel |

Cast Plain |

Plain Carbon Steel |

Bronze |

Brass |

Copper |

Aluminium |

Plastics |

glass, tile floors, wall |

|

|

HSS4241 |

× |

√ |

× |

√ |

√ |

√ |

not good |

√ |

× |

|

HSS6542/M2 |

not good |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

× |

|

HSS Co/M35 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

× |

|

HSS Co/M42 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

× |

Shipping and Packing

Shipping: Express delivery, air shipping, sea shipping are available for your request. Usual delivery time is 5-10days after receiving the advance payment; For the customized product, 15-30 days after receiving the advance payment.

Packing: We also supply single pvc bag,paper bag,colored plastic square box,transparent plastic box,skin card,sandwich and so on packages with size, logo,brand and other information.

FAQ

Q: Are you professional manufacturer of HSS twist drill bits?

A: Yes,JIANGSU HAOKE MATERIAL TECH CO.,LTD is a professional factory that main products is HSS TWIST DRIL BITS.Following took a few photos of our workshop production and warehouse.

Q: Is OEM available?

A: Yes, OEM and customization are available. Graved logo marker,Laser logo marker,, customized packing. Printed Inner box, Carton box.

Q: Are samples available?

A: Yes, you can ask some samples for testing after confirming our prices, but please pay the sample and freight fee, the sample fee will be returned to you after you making official order.

Q: What is your payment terms?

A: T/T,L/C,D/A,D/P,Paypal,Western Union,for different circumstances.

Q: What's your delivery way?

A: Express delivery, air shipping, sea shipping are available for your request.

Q: What's your delivery time?

A: Usual delivery time is 5-10days after receiving the advance payment; For the customized product, 15-30 days after receiving the advance payment.