T27 vs T29 Flap Discs: What's the Difference and Which One to Choose?

If you work in metalworking or fabrication, flap discs are a toolbox staple. But two common types—T27 and T29—often cause confusion. While they look similar, they serve distinct purposes: choosing the wrong one wastes time and hurts results.

This guide breaks down their key differences, strengths, and ideal uses—so you’ll pick the right disc every time.

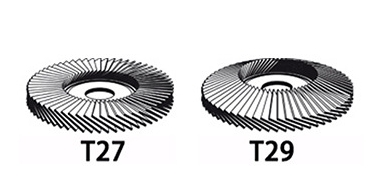

Core Difference: Flat vs. Conical Design

The most fundamental distinction between T27 and T29 flap discs lies in their shape and sanding surface geometry. This design difference directly impacts how they interact with workpieces and the results they deliver.

■T27 Flap Discs: feature a completely flat sanding surface. The abrasive flaps are bonded tightly to a rigid, flat backing plate, creating a stable, even contact area with the workpiece. This design prioritizes precision and smoothness over aggressive material removal.

■T29 Flap Discs: have a slightly curved, raised sanding surface. The abrasive flaps are angled outward from the center of the backing plate, forming a gentle cone shape. This angled design concentrates pressure on a smaller contact area, boosting cutting power and making it easier to reach contoured or hard-to-access areas.

Side-by-Side Comparison: T27 vs. T29

|

Comparison Metric |

T27 Flap Discs |

T29 Flap Discs |

| Design | Flat sanding surface; flaps bonded to a flat backing plate | Conical/curved sanding surface; flaps angled outward |

| Ideal Grinding Angle | 0°–15° (shallow, flat contact) | 10°–25° (angled contact for contours) |

| Abrasive Aggressiveness | Mild to moderate; focuses on smoothness | Aggressive; high material removal rate |

| Finish Quality | Smooth, uniform surface; minimizes scratches | Rougher initial finish; requires secondary sanding for smoothness |

| Stability | High; flat design reduces vibration during use | Moderate; angled flaps may vibrate slightly on flat surfaces |

| Best For | Flat surface finishing, weld blending, scratch removal, final smoothing | Deburring, edge chamfering, weld beveling, contour grinding, casting cleanup |

When to Choose T27: Prioritize Smoothness

Choose T27 when you need a smooth, consistent finish on flat/slightly curved surfaces. Top uses:

▪Blending welds on flat metal for a seamless look

▪Removing light scratches from aluminum, steel, or stainless steel

▪Final finishing on parts needing a professional polish

▪Sanding large flat areas (e.g., metal panels) for uniformity

Pro tip: Use 120#–400# grits for ultra-smooth finishes, or 36#–80# for light material removal first.

When to Choose T29: Prioritize Speed & Access

Choose T29 for fast material removal or non-flat surfaces. Ideal uses:

▪Deburring sharp edges or casting flash

▪Chamfering metal pipes, sheets, or holes

▪Shaping welds or prepping bevels for welding

▪Grinding contours or hard-to-reach areas (e.g., pipe joints)

▪Cleaning rough castings before processing

Pro tip: Use 36#–80# grits for heavy deburring, 120# for lighter contour work.

Myth Busting: Common Misconceptions

Let’s clear up a few myths that often confuse buyers:

- Myth 1: T29 is "better" than T27. Fact: They’re for different jobs—T29 ruins flat finishes, T27 struggles with deburring.

- Myth 2: They need different tools. Fact: Both fit standard angle grinders.

- Myth 3: Grit options differ. Fact: Both come in 36#–400# grits.

In short, T27 and T29 flap discs each have their own strengths—T27 excels at delivering smooth, uniform finishes on flat or slightly curved surfaces like welded metal sheets, while T29 shines at fast material removal and accessing contours, edges, or hard-to-reach spots for tasks like deburring or chamfering. Since both fit standard angle grinders and offer the same grit ranges, the best approach is to select based on your core need: prioritize smoothness with T27, or speed and access with T29.

Post time: Nov-21-2025